View Large

View Large

Six graining method

Full electronic scale of materials, bitumen and filler

Equipped with additive system (cement, stone powder, pigment, etc.)

Twin shaft mixer, with anti-wear picks and a puzzled inner wall made of ST sheet

Equipped with wall heater with oil heater system

Asphalt storage silo (equipped with an oil heater to prevent the asphalt from cooling)

Elevator for lifting hot materials (for lifting hot materials exiting the dryer)

Elevator lifter filler or other additives

It has footstools on all floors for visiting and servicing different parts of the tower

Call to order

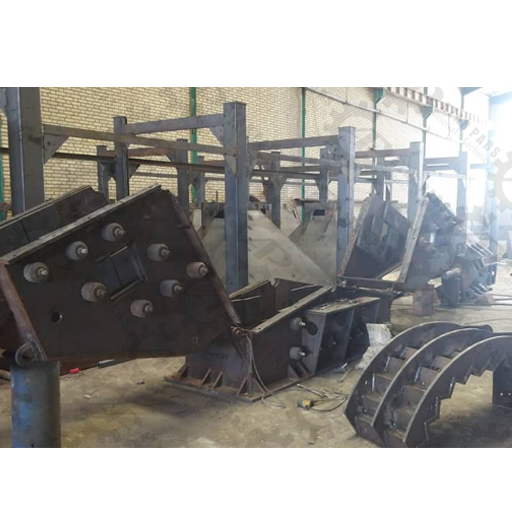

Dryer or rotary oven

The material dryer or rotary kiln is of the ring type and is equipped with an automatic multi-burner turbojet burner for the production of hot materials.

The chassis of the dryer is made of standard steel beams – the pulleys are made of special alloys with very strong bearings and a steel shaft.

Call to order

Silage of cold materials

The seeds are piled up in silos to reach the rotary kiln or dryer. Each silo contains materials of different grades and sizes, which are poured from the gates on each silo onto the conveyor belt and transferred to the furnace.

Call to order

Dust filters

The machines of this collection are equipped with dust filters and filler production to add to asphalt production, which is approved by the Environmental Organization.

Call to order

Bag filter

A bag filter with a heavy metal housing, consisting of hundreds of heat-resistant silicone bags, which increases the ability to absorb very fine dust particles created inside the dryer and prevents them from being released into the air.

Call to order

bitumen flax

In order to store and supply the bitumen consumed by the factory in different capacities, it is designed and built equipped with a heater to keep the bitumen fluid in the cold seasons and regions, along with a protective wall and thermal insulation.

Call to order

Control panel and operator booth

The control panel has an intelligent asphalt curing system, which has the ability to program all types of asphalt curing. This board is installed inside the operator’s cabin for the comfort of the operator.

Call to order

Additional equipment

Additional equipment designed and produced in Azarpars complex on asphalt factories for the purpose of recycling and reusing scraped asphalt, as well as the production of colored asphalt, polymer, etc.